<Back to Index>

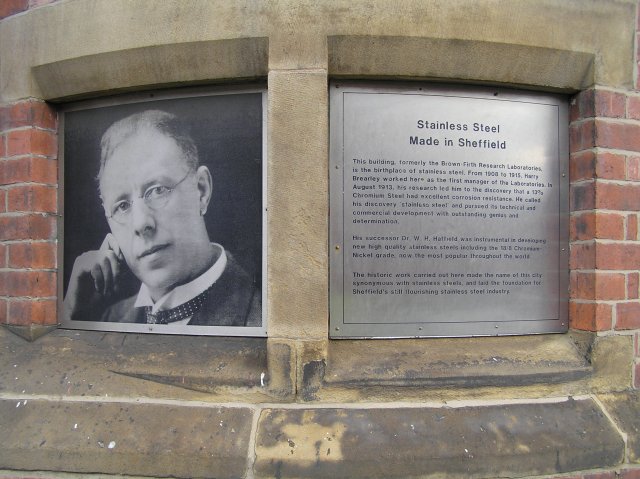

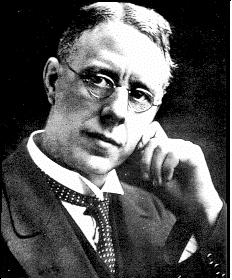

- Inventor Harry Brearley, 1871

- Painter Anders Leonard Zorn, 1860

- Daimyo of Echigo Province Uesugi Kenshin, 1530

PAGE SPONSOR

Harry Brearley (February 18, 1871 – August 12, 1948) is usually credited with the invention of "rustless steel" (later to be called "stainless steel") in the anglophone world, although Krupp filed a patent for its brand of Nirosta a few months before Brearley's breakthrough.

Brearley was born in Sheffield, England. His life had humble beginnings as the son of a steel melter. He left school at the age of twelve to enter his first employment as a labourer in one of the city's steelworks, being transferred soon afterwards to the post of general assistant in the company's chemical laboratory. For several years, in addition to his laboratory work, he studied at home and later in formal evening classes, to specialize in steel production techniques and associated chemical analysis methods.

By his early thirties, Brearley had earned a reputation as an experienced professional and for being very astute in the resolution of practical, industrial, metallurgical problems. It was in 1908, when two of Sheffield's principal steelmaking companies innovatively agreed to jointly finance a common research laboratory (Brown Firth Laboratories) that Harry Brearley was asked to lead the project.

Brearley died in 1948, at Torquay, a coastal resort town in Devon, south west England. He is buried at Sheffield Cathedral.

In the troubled years immediately before World War I, arms manufacturing increased significantly in the UK, but practical problems were encountered due to erosion (excessive wear) of the internal surfaces of gun barrels. Brearley began to research new steels which could better resist the erosion caused by high temperatures (rather than corrosion, as is often mentioned in this regard). He began to examine the addition of chromium to steel, which was known to raise the material’s melting point, as compared to the standard carbon steels. The research concentrated on quantifying the effects of varying the levels of carbon (C, at concentrations around 0.2 weight %) and chromium (Cr, in the range of 6 to 15 weight %).

In order to undertake metallography to study the microstructure of the experimental alloys (the main factor responsible for a steel's mechanical properties) it was necessary to polish and etch the metallic samples produced. For a carbon steel, a dilute solution of nitric acid in alcohol is sufficient to produce the required etching, but Brearley found that the new chromium steels were very resistant to chemical attack.

It was probably Harry Brearley’s upbringing in Sheffield, a city famous for the manufacture of cutlery since the 16th century, which led him to appreciate the potential of these new steels for applications not only in high temperature service, as originally envisioned, but also in the mass production of food related applications such as cutlery, saucepans and processing equipment etc. Up to that time carbon steel knives were prone to unhygienic rusting if they were not frequently polished and only expensive sterling silver or EPNS cutlery was generally available to avoid such problems. With this in mind Brearley extended his examinations to include tests with food acids such as vinegar and lemon juice, with very promising results.

Brearley initially called the new alloy "rustless steel"; the more euphonic "stainless steel" was suggested by Ernest Stuart of R.F. Mosley's, a local cutlery manufacturer, and eventually prevailed. It is reported that the first true stainless steel, a 0.24 wt % C, 12.8 wt % Cr ferrous alloy, was produced by Brearley in an electric furnace on August 13, 1913. He was subsequently awarded the Iron and Steel Institute's Bessemer Gold Medal in 1920.

Virtually

all research projects into the further development of stainless steels

were interrupted by the 1914 - 18 War, but efforts were renewed in the

1920s. Harry Brearley had left the Brown Firth Laboratories in 1915,

following disagreements regarding patent rights, but the research continued under the direction of his successor, Dr. W.H. Hatfield.

It is Hatfield who is credited with the development, in 1924, of a

stainless steel which even today is probably the widest used alloy of

this type, the so-called "18/8", which in addition to chromium, includes nickel (Ni) in its composition (18 wt % Cr, 8 wt % Ni).