<Back to Index>

- Inventor Lemuel Wellman Wright, 19th Century

- Engineer William Barnett, 19th Century

PAGE SPONSOR

Lemuel Wellman Wright is the name recorded in the British patent index for the patents listed below, however some texts use Lemuel Willman Wright to refer to the author of the same patents, and there are contemporary references to an American from Massachusetts, Lemuel William Wright, who patented machinery and created a factory to make pins in London. The patent subject index lists the author of a patent for making pins in 1824 as Lemuel Wellman Wright (patent number 4955 of 1824), and has no other similar names recorded related to pins, so unless the patent office publication is in error, all these references appear to be to the same inventor.

Lemuel Wellman Wright was responsible for a considerable number of British patents in the first half of the 19th century, for example :

- No 4507 of 1820 "Combination of machinery for making bricks and tiles"

- No 4955 of 1824 "Machinery for making pins; also combinations of such machinery"

- No 5154 of 1825 "Machinery for washing, cleansing, or bleaching linens, cottons and other fabrics, good or fibrous substances"

- No 5400 of 1826 "Construction of Trucks or Carriages; - applicable to other useful purposes"

- No 5473 of 1827 "Combination and Arrangement of machinery for making metal screws"

- No 5544 of 1827 "Construction of Cranes"

- No 5638 of 1828 "Construction of Wheeled Carriages"

- No 5703 of 1828 "Machinery for making screws"

- No 6525 of 1833 "Combination and arrangement of machinery whereby known agents may be employed in producing power"

- No 6655 of 1834 "Machinery for refrigerating fluids"

- No 7251 of 1836 "Machinery for bleaching or cleansing linens, cottons, or other fabrics, goods, or other fibrous substances"

- No 7348 of 1837 "Machinery for bleaching or cleansing linens, cottons, or other fabrics, goods, or other fibrous substances"

- No 8028 of 1839 "Machinery for bleaching or cleansing linens, cottons, or other fabrics, goods, or other fibrous substances"

- No 9787 of 1843 "Machinery for bleaching various fibrous substances"

In the 1827 patent (no 5544) Lemuel describes two forms of crane. One operated by hand and another by compressed air using am engine similar to a steam engine. This afforded advantages for mobile cranes where a central plant could provide compressed air.

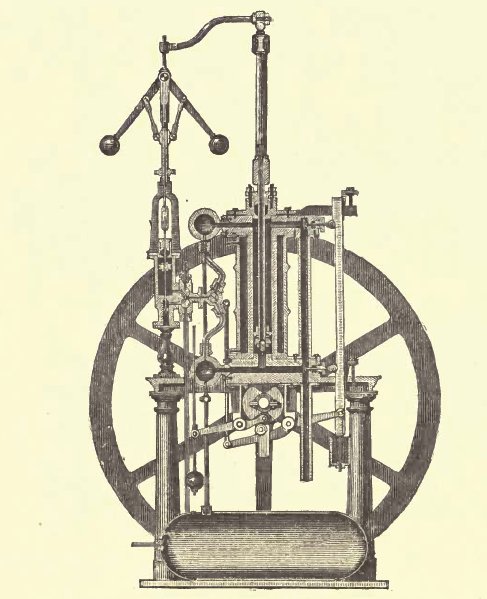

Lemuel Wright is also responsible for one of the very early patents for internal combustion engines, British patent number 6525 of 1833. One of the earliest sources to describe his engine and patent is the scientist and engineer Dugald Clerk (later Sir Dugald Clerk FRS) in his book "Gas and Oil Engines" first published in 1886. Dugald Clerk is the creator of the first commercial engine operating on the 2 - stroke cycle with in - cylinder compression, and is often considered to be the originator of the modern 2 - stroke engine. In summarizing the importance of patents prior to 1860 (when the internal combustion became a commercial reality), Clerk states : "The greatest credit is due to Wright and Barnett. Wright very closely proposed the modern non - compression system, Barnett the modern compression system.".

"In

this specification the drawings are very complete and the details are

carefully worked out. The explosion of a mixture of inflammable gas and

air acts directly upon the piston, which acts through a connecting rod

upon a crank - shaft. The engine is double - acting, the piston receiving

two impulses for every revolution of the crank - shaft. In appearance it

resembles a high pressure steam engine of the kind known as the table

pattern. The gas and air are supplied to the motor cylinder from

separate pumps through two reservoirs, at a pressure a few pounds above

atmosphere, the gases (gas and air) enter spherical spaces at the ends

of the motor cylinder, partly displacing the previous contents, and are

ignited while the piston is crossing the dead centre. The explosion

pushes the piston up or down through its whole stroke; at the end

of the stroke the exhaust valve opens and the products of combustion are

discharged during the return, excepting the portion remaining in the

spaces not entered by the piston. The ignition is managed by an external

flame and touch - hole.

The author (Clerk)

has been unable to find whether the engine was ever made, but the

knowledge of the detail essential to a working gas engine shown by the

drawings indicates that it or some similar machine had been worked by

the inventor.

Both

cylinder and piston are water - jacketed, as would have been necessary

in

a double - acting gas engine to preserve the working parts from damage

from the intense heat of the explosion. This is the earliest drawing in

which this detail is properly shown."

The engine depicted uses a centrifugal governor to control the speed of the engine. Early internal combustion engines did not have the benefit of a throttle,

and with separate air and gas pumps and the need to keep the gas / air

mixture is a specific range to achieve reliable ignition and combustion,

the control of speed was significantly different from steam engines.

For this reason many early engines operate on a hit - and - miss principle, either a full charge of gas and air or no gas at all.

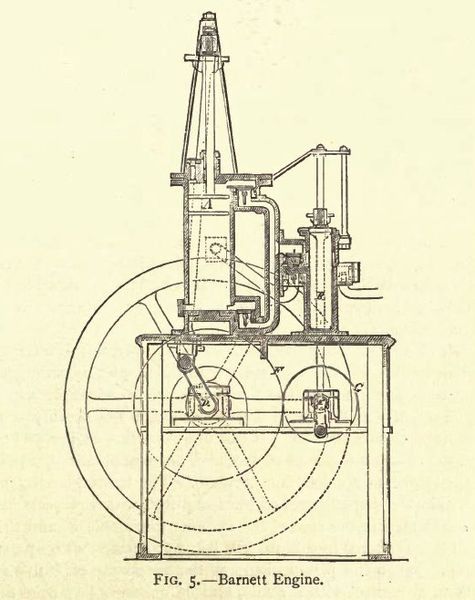

William Barnett is described as a 'founder' in his 1836 patent, and an 'ironfounder' in his 1838 patent, both times at Brighton, UK. His patent of 1836 is recorded in the Mechanics Magazine as "Certain improvements for generating and purifying gas for the purposes of illumination".

William Barnett was an engineer involved in the early development of internal combustion engines, and his work and patent are described over several pages in Dugald Clerk's book on Gas and Oil Engines. In Barnett's UK patent (No 7615 of 1838), which was entitled "Production of motive - power", Clerk states that "Barnett's inventions as described in his specification are so important that they require more complete description than has been accorded to earlier inventors", and he then proceeds to discuss Barnett's patent over several pages.

The patent describes three types of internal combustion engine run using gas as a fuel. These use two key inventions that were important to the early commercial gas engines (which do not appear until over 20 years later).

- One of the engines described in the patent uses compression of the fuel / air mixture in the power cylinder, the system which Clerk describes as "now so largely used in gas engines. The Frencheman, Lebon, it is true, described an engine using compression, in the year 1801, but his cycle is not in any way similar to that proposed by Barnett, or used in modern gas engines".

- The patent also describes a method for igniting the gas / air mixture within the cylinder using a flame transferred into the cylinder via an 'igniting cock'. This was a mechanism extensively used in many of the early commercial gas engines in the latter part of the 19th century.

The engines themselves are of considerable interest as precursors, not of the first commercial gas engines (e.g., Lenoir engine in 1860, which used the 2 - stroke cycle without compression, or the Otto and Langen atmospheric engines), but rather of the later generation of engines including Otto's engines operating on the 4 - stroke cycle and Dugald Clerk's engine operating on the 2 - stroke cycle, both with compression of the gas / air mixture in the cylinder.

Note that all three engines operate on the 2 - stroke cycle, as did most early engines (the competition was steam engines, which also operate on the 2 - stroke cycle, and are usually double acting so every stroke is a power stroke). It was a remarkable leap to discover that, for internal combustion engines, the 4 - stroke cycle with three non - power strokes could deliver both economy and performance, see Alphonse Beau de Rochas who patented the idea in 1861, and Otto who made commercial engines using the 4 - stroke cycle after his earlier work with atmospheric engines. All three of Barnett's engines were vertical engines with a layout similar to steam table engines.

- The first engine is single acting using the 2 - stroke cycle, with separate pumps for gas and air, and a power cylinder. This cylinder is connected directly to a receiver vessel in which the combustion is initiated, the expansion flows into the power cylinder driving the piston. Timing of inlet and exhaust is via a piston valve, and an exhausting pump may be added to remove exhaust gases from the receiver prior to the new charge being forced in by the pumps. This is described as optional for smaller engines, as the exhaust gases are not so much a problem for them.

- The second engine is a double acting version of the first, i.e., combustion is alternately one side and then the other side of the piston. The operating principles are otherwise the same.

- The third engine is also double acting using the 2 - stroke cycle, and although it has the gas and air pumps of the others, it has an exhaust port uncovered by the piston towards the end of the power stroke, allowing the exhaust gases to exit and the fresh charge to enter the power cylinder and then be compressed by the piston prior to ignition at the end of the compression stroke.

The displayed image of the third engine reveals a double acting engine in the style of a steam table engine. The vertical cylinder is not water cooled. There is a central square exhaust port on the cylinder wall uncovered by the piston. A separate pump operates at twice engine speed to deliver the fresh charge to either end of the cylinder and purge the cylinder of exhaust gases, but the piston compresses the charge once the exhaust port is covered.

Dugald Clerk describes several patents on the internal combustion engine between 1839 and 1854, but states that "Of these patents, by far the most important is Barnett's". Praise indeed from an eminent engineer who would subsequently receive a KBE and become a fellow of the Royal Society.