<Back to Index>

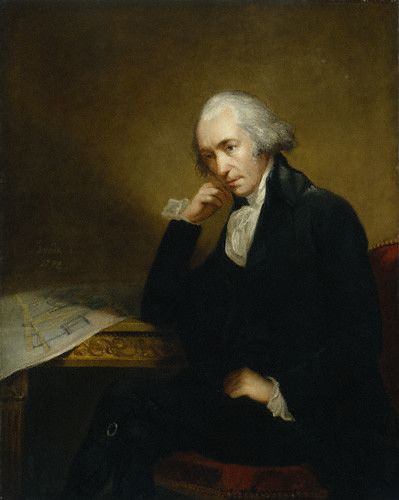

- Engineer James Watt, 1736

- Painter Paul Cézanne, 1839

- General Robert Edward Lee, 1807

PAGE SPONSOR

James Watt, FRS, FRSE (19 January 1736 – 25 August 1819) was a Scottish inventor and mechanical engineer whose improvements to the Newcomen steam engine were fundamental to the changes brought by the Industrial Revolution in both the Kingdom of Great Britain and the world.

While working as an instrument maker at the University of Glasgow, Watt became interested in the technology of steam engines. He realised that contemporary engine designs wasted a great deal of energy by repeatedly cooling and re-heating the cylinder.

Watt introduced a design enhancement, the separate condenser, which

avoided this waste of energy and radically improved the power,

efficiency, and cost-effectiveness of steam engines. Watt

attempted to commercialise his invention, but experienced great

financial difficulties until in 1775 he entered a partnership with Matthew Boulton. The new firm of Boulton and Watt was

eventually highly successful and Watt became a wealthy man. In

retirement, Watt continued to develop new inventions though none were

as significant as his steam engine work. He died in 1819 at the age of

83. The official SI unit of power, the watt, is named in his honour. James Watt was born on 19 January 1736 in Greenock, Renfrewshire, a seaport on the Firth of Clyde. His father was a shipwright, ship owner and contractor, and served as the town's chief baillie, while his mother, Agnes Muirhead, came from a distinguished family and was well educated. Both were Presbyterians and strong Covenanters. Watt's grandfather, Thomas Watt, was a mathematics teacher and baillie to the Baron of Cartsburn. Watt did not attend school regularly; initially he was mostly schooled at home by his mother but later he attended Greenock grammar school. He exhibited great manual dexterity and an aptitude for mathematics, although Latin and Greek failed to interest him. When he was 18, his mother died and his father's health began to fail. Watt travelled to London to study instrument-making for a year, then returned to Scotland, settling in the major commercial city of Glasgow intent on setting up his own instrument-making business. However, because he had not served at least seven years as an apprentice, the Glasgow Guild of Hammermen (any artisans using hammers)

blocked his application, despite there being no other mathematical

instrument makers in Scotland. Watt was saved from this impasse by the

arrival of astronomical instruments to the University of Glasgow that required expert attention. Watt restored them to working order and was remunerated. These instruments were eventually installed in the Macfarlane Observatory.

Subsequently three professors of the University offered him the

opportunity to set up a small workshop within the university. It was

established in 1758 and one of the professors, the physicist and chemist Joseph Black, became Watt's friend. In

1764, Watt married his cousin Margaret Miller, with whom he had five

children, two of whom lived to adulthood: James Jr. (1769 – 1848) and

Margaret (1767 – 1796). His wife died in childbirth in 1772. In 1777 he

married again, to Ann MacGregor, daughter of a Glasgow dye-maker, with

whom he had two children: Gregory (1777 – 1803) and Janet (1779 –

1794).

Ann died in 1832. Watt

was an enthusiastic inventor with a fertile imagination. He was skilled

with his hands, and was also able to perform systematic scientific

measurements that could quantify the improvements he made and produce a

greater understanding of the phenomena with which he was working. He

was greatly respected by other prominent men of the Industrial Revolution. He was an important member of the Lunar Society, and was a much sought-after conversationalist and companion, always interested in expanding his horizons. His

personal relationships with his friends and partners were always

congenial and long-lasting. Watt was a prolific correspondent. During

his years in Cornwall, he wrote long letters to Boulton several times per week. He was averse to publishing his results in, for example, the Philosophical Transactions of the Royal Society however, and instead preferred to communicate his ideas in patents. He

was a rather poor businessman, and especially hated bargaining and

negotiating terms with those who sought to utilize the steam engine.

Until he retired, he was always much concerned about his financial

affairs, and was something of a worrier. His health was often poor. He

was subject to frequent nervous headaches and depression. Four years after Watt had opened his workshop, his friend, Professor John Robison,

called his attention to the use of steam as a source of power, and Watt

began to experiment with it. Watt had never seen an operating steam

engine, but he tried constructing a model. It failed to work

satisfactorily, but he continued his experiments and began to read

everything he could about the subject. He independently discovered the

importance of latent heat in

understanding the engine, which, unknown to him, Black had famously

discovered some years before. He learned that the University owned a

model Newcomen engine, but it was in London for repairs. Watt got the university to have it returned, and he made the repairs in 1763. It

too just barely worked, and after much experimentation he showed that

about 80% of the heat of the steam was consumed in heating the cylinder, because the steam in it was condensed by an injected stream of cold water. His critical insight was to cause the steam to condense in a separate chamber apart from the piston,

and to maintain the temperature of the cylinder at the same temperature

as the injected steam. He soon had a working model by 1765. Now

came a long struggle to produce a full-scale engine. This required more

capital, some of which came from Black. More substantial backing came

from John Roebuck, the founder of the celebrated Carron Iron Works, near Falkirk, with whom he now formed a partnership. But the principal difficulty was in machining the piston and cylinder. Iron workers of the day were more like blacksmiths than machinists, so the results left much to be desired. Much capital was spent in pursuing the ground-breaking patent. Strapped for resources, Watt was forced to take up employment first as a surveyor, then as a Civil engineer for eight years. Roebuck went bankrupt, and Matthew Boulton, who owned the Soho Foundry works near Birmingham, acquired his patent rights. An extension of the patent to 1800 was successfully obtained in 1775. Watt

finally had access to some of the best iron workers in the world. The

difficulty of the manufacture of a large cylinder with a tightly

fitting piston was solved by John Wilkinson who had developed precision boring techniques for cannon making at Bersham, near Wrexham, North Wales. Watt and Boulton formed a hugely successful partnership (Boulton & Watt), which lasted for the next twenty-five years. Finally,

in 1776, the first engines were installed and working in commercial

enterprises. These first engines were used for pumps and produced only

reciprocating motion to move the pump rods at the bottom of the shaft.

Orders began to pour in and for the next five years Watt was very busy

installing more engines, mostly in Cornwall for pumping water out of mines. These

early engines were not actually manufactured by Bolton & Watt, but

were made by others according to drawings made by Watt, who served in

the role of consulting engineer. The erection of the engine and its

shakedown was supervised by Watt, at first, then by men in their

employ. These were large machines. The first, for example, had a

cylinder with a diameter of some 50 inches and an overall height

of about 24 feet, and required the construction of a purpose-built

building to house it. The payment due to the company was set at an

annual rate equal to one third of the coal saved in comparison to that

used by a Newcomen engine doing comparable work. The

field of application of the invention was greatly widened only after

Boulton urged Watt to convert the reciprocating motion of the piston to

produce rotational power for grinding, weaving and milling. Although a crank seemed the logical and obvious solution to the conversion Watt and Boulton were stymied by a patent for this, whose holder, James Pickard,

and associates proposed to cross-license the external condenser. Watt

adamantly opposed this and they circumvented the patent by their sun and planet gear in 1781. Over

the next six years, he made a number of other improvements and

modifications to the steam engine. A double acting engine, in which the

steam acted alternately on the two sides of the piston was one. He

described methods for working the steam "expansively" (i.e., using

steam at pressures well above atmospheric). A compound engine, which

connected two or more engines was described. Two more patents were

granted for these in 1781 and 1782. Numerous other improvements that

made for easier manufacture and installation were continually

implemented. One of these included the use of the steam indicator which produced an informative plot of the pressure in the cylinder against its volume, which he kept as a trade secret. Another important invention, one of which Watt was most proud of, was the Parallel motion which

was essential in double-acting engines as it produced the straight line

motion required for the cylinder rod and pump, from the connected

rocking beam, whose end moves in a circular arc. This was patented in 1784. A throttle valve to control the power of the engine, and a centrifugal governor, patented in 1788, to

keep it from "running away" were very important. These improvements

taken together produced an engine which was up to five times as

efficient in its use of fuel as the Newcomen engine. Because of the danger of exploding boilers,

which were in a very primitive stage of development, and the ongoing

issues with leaks, Watt restricted his use of high pressure steam – all

of his engines used steam at near atmospheric pressure. In 1794 the partners established Boulton and Watt to

exclusively manufacture steam engines, and this became a large

enterprise. By 1824 it had produced 1164 steam engines having a total

nominal horsepower of about 26,000. Boulton proved to be an excellent businessman, and both men eventually made fortunes. Edward

Bull started erecting engines for Boulton and Watt in Cornwall in 1781.

By 1792 he had started making engines of his own design, but which

contained a separate condenser, and so infringed Watt's patents. Two

brothers, Jabez Carter Hornblower and Jonathan Hornblower Jnr also

started erecting engines about the same time. Others began to modify

Newcomen engines by adding a condenser, and the mine owners in Cornwall

became convinced that Watt's patent could not be enforced. They started

to withhold payments due to Boulton & Watt, which by 1795 had

fallen from the £21,000 due to only £2500 received. Watt

was forced to go to court to enforce his claims. He

first sued Bull in 1793. The jury found for Watt, but the question of

whether or not the original specification of the patent was valid was

left to another trial. In the meantime, injunctions were issued against

the infringers, forcing their payments of the royalties to be placed in

escrow. The trial on determining the validity of the specifications

which was held in the following year was inconclusive, but the

injunctions remained in force and the infringers, except for Jonathan

Hornblower, all began to settle their cases. Hornblower was soon

brought to trial and the verdict of the four judges (in 1799) was

decisively in favor of Watt. Boulton & Watt never collected all

that was owed them, but the disputes were all settled directly between

the parties or through arbitration. These trials were extremely costly

in both money and time, but ultimately were successful for the firm. Before

1780 there was no good method for making copies of letters or drawings.

The only method sometimes used was a mechanical one using linked

multiple pens. Watt at first experimented with improving this method,

but soon gave up on this approach because it was so combersome. He

instead decided to try to physically transfer some ink from the

original to another sheet of paper which was thin enough for the ink to

go through to the other side, thus reproducing the writing exactly. Watt

started to develop the process in 1779, and made many experiments to

formulate the ink, select the thin paper, to devise a method for

wetting the special thin paper, and to make a press suitable for

applying the correct pressure to effect the transfer. All of these

required much experimentation, but he soon had enough success to patent

the process a year later. Watt formed another partnership with Boulton

(who provided financing) and James Keir (to

manage the business) in a firm called James Watt & Co. The

perfection of the invention required much more development work before

it could be routinely used by others, but this was carried out over the

next few years. Boulton and Watt gave up their shares to their sons in

1794. It became a commercial success and was widely used in offices even into the twentieth century. From an early age Watt was very interested in chemistry. In late 1786, while in Paris, he witnessed an experiment by Berthollet in

which he reacted hydrochloric acid with manganese dioxide to produce

chlorine. He had already found that aqueous solutions of it could

bleach textiles, and had published his findings, which aroused great

interest among many potential rivals. When Watt returned to Britain, he

began experiments along these lines with hopes of finding a

commercially viable process. He discovered that a mixture of salt, manganese dioxide and

sulfuric acid could produce chlorine, so he thought he had the

beginnings of a cheaper method. He passed the chlorine into a weak

solution of alkali, and obtained a turbid solution that appeared to

have good bleaching properties. He soon communicated these results to

James McGrigor, his father-in-law, who was a bleacher in Glasgow.

Otherwise he tried to keep his method a secret.

With

McGrigor, and his Wife Annie, he started to scale up the process, and

in March of 1788, McGrigor was able to bleach 1500 yards of cloth to

his satisfaction. However, about this time Berthollet discovered the

salt and sulfuric acid route, and published it so it became public

knowledge. Many others began to experiment with improving the process,

which still had many shortcomings, not the least of which was the

problem of transporting the liquid product. His rivals soon overtook

him in developing the process, and he dropped out of the race. It was

not really until in 1799 Charles Tennant patented a process for producing solid bleaching powder (calcium hypochlorite) that it really took off and became a huge commercial success.

Watt retired in 1800, the same year that his fundamental patent and partnership with Boulton expired. The famous partnership was transferred to the men's sons, Matthew Boulton and James Watt Jr. Longtime firm engineer William Murdoch was soon made a partner and the firm prospered. Watt

continued to invent other things before and during his semi-retirement.

He invented a new method of measuring distances by telescope,

improvements in the oil lamp, a steam mangle and

a machine for copying sculptures. Within his home in Handsworth Heath,

Staffordshire, Watt made use of a garret room as a workshop, and it was

here that he worked on many of his inventions. He

and his second wife travelled to France and Germany, and he purchased

an estate in Wales at Doldowlod House, one mile south of Llanwrthwl, which he much improved. He died on 25 August 1819 at his home "Heathfield" in Handsworth, Birmingham, England, at the age of 83. He was buried on 2 September. The

garret room workshop that Watt used in his retirement was left locked

and untouched until 1853, when it was first viewed by his biographer

J.P. Muirhead. Thereafter, it was occasionally visited, but left

untouched, as a kind of shrine. A proposal to have it transferred to

the Patent Office came to nothing. When the house was due to be

demolished in 1924, the room and all its contents were presented to the Science Museum, where it was recreated in its entirety. It

remained on display for visitors for many years, but was walled-off

when the gallery it was housed in closed. The workshop remains intact,

and preserved, and there are plans for it to go on display again at

some point in the near future. As with many major inventions, there is some dispute as

to whether Watt was the original sole inventor of some of the

inventions he patented. There is no dispute, however, that he was the

sole inventor of his most important invention, the separate condenser,

the parallel motion linkage, nor of his single other commercially

successful invention, the copy machine. It

was his practice to sometimes pre-empt others' ideas which were known

to him by filing patents with the intention of securing credit for the

invention for himself, and ensuring that no one else was able to

practice it. As he states in a letter to Boulton of 17 August 1784: Some argue that his prohibitions on his employee William Murdoch from working with high pressure steam on his steam road locomotive experiments delayed its development. Watt patented the application of the sun and planet gear to steam in 1781 and a steam locomotive in

1784, both of which have strong claims to have been invented by his

employee, William Murdoch. Watt himself described the provenance of the

invention of the sun and planet gear in a letter to Boulton from Watt

dated 5 January 1782: The

patent was never contested by Murdoch, who remained an employee of

Boulton and Watt for most of his life, and Boulton and Watt's firm

continued to use the sun and planet gear in their rotative engines,

even long after the patent for the crank expired in 1794.